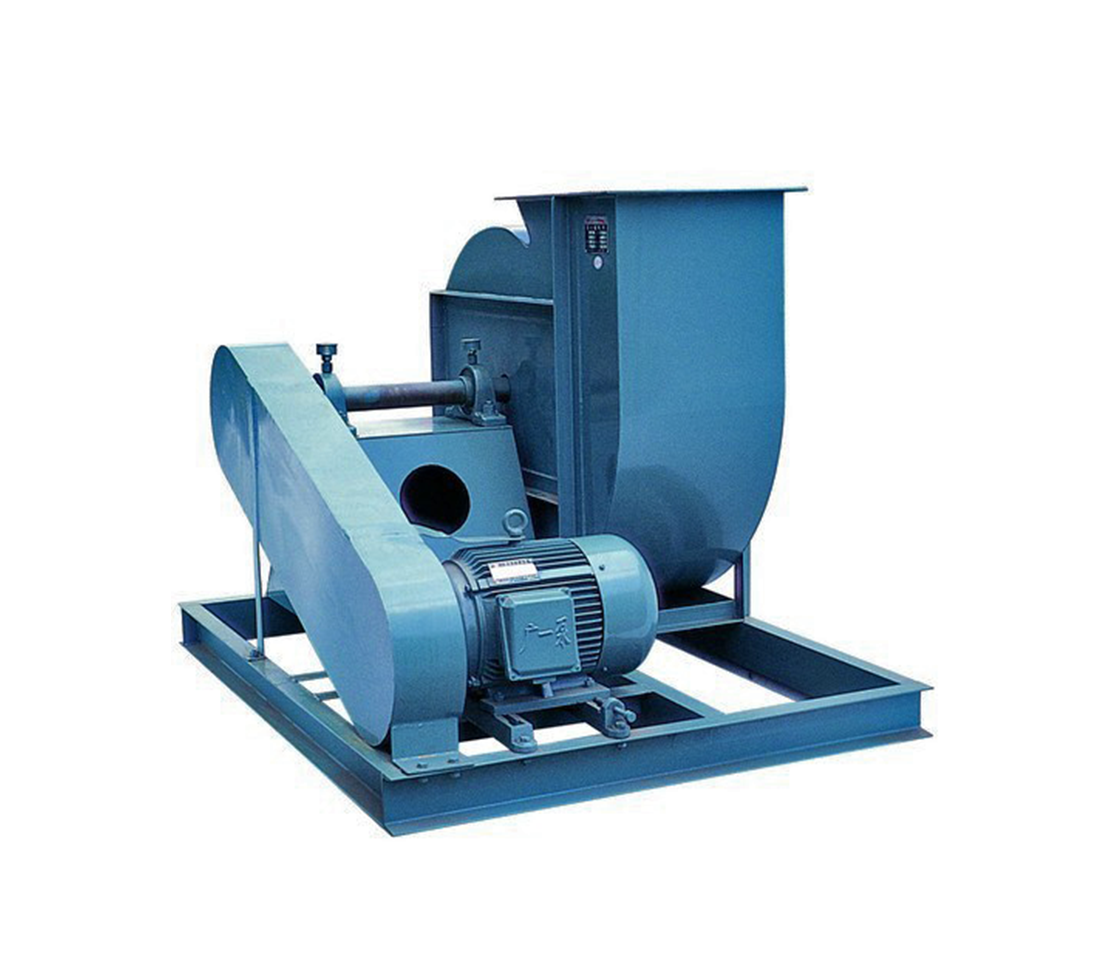

Centrifugal Fans

We (MPEP) design, manufacture and supply a range of high quality centrifugal blowers that find application in foundries, chemical, steel plants, paper, petrochemical plants, cement, plastics, fertilizers and other industries. Designed using the advanced technology, these blowers are energy efficient, compact, lightweight, durable, cost-effective and requires little or no maintenance over the working life. Further, these are also custom designed as per the requirements of the clients. Cylindrical multi blade rotor in cycloid steel casing. The rotor is driven by a motor placed internally or externally. Air is expelled centrifugally, if required under very high pressure.

| Applications | Fan Types | Product Description : | SPECIAL FEATURES - | Standard Arrangement/Accessories : |

|---|---|---|---|---|

| Dust Collection and Control | Forward Curved | A large selection of outlet positions, casing geometries, casing thicknesses | Dynamically balanced impellers | Arrangement 1 : Impeller wheel is overhung, two bearings on a base. The fan and motor are separately mounted to a unitary base |

| Pollution-control equipment | Radial Curved | Casing types Low/Medium/High pressure (up to 800 mm WC) | High Efficiency Single thickness blade | Arrangement 3 : The impeller wheel is supported by fan housing with one bearing |

| Industrial processing, | Backward Curved Rotor | Material Steel, AISI, Aluminum, special alloys | High temperature construction | Arrangements 2, 4 - 9 can also be made if needed |

| Material Handling | Combines Forward - Backward Curved | Impeller types, Outlet position As required | Compact design for restricted space | Silencer Sound |

| Chemical Process | Low Pressure | Single inlet to facilitate fixing of ducts at inlet and outlet | AC Variable speed drive | Enclosures |

| Pressure Blower | Medium Pressure | Suitable for Capacities upto 200000 cfm | Damper controlled | Outlet/Inlet damper |

| Painting plants / Spray Booths | High Pressure | Flame-proof, High temperature (up to 250 0C, gas-tight, de-contaminable, corrosion resistant, shock proof | Single and Double width construction | Counter Flange |

| Food & Beverage industry | Belt Drive | Surface treatment Primer, finish, Hot dip galvanized, special | Trouble free & Lower noise level operation | Vibration Attenuator Case Insulation |

| Heating, ventilation, and air conditioning | Single/Double Inlet | Premium Efficiency Airfoil blade | Flexible Connection | |

| Incinerators | Direct Coupled | Non-Sparking & Overloading | Inlet cone, Protection grill, Wall cowl | |

| Humidification / Heat exchangers | Belt, coupled Direct drive | Feet for horizontal/vertical position | ||

| Induced Draft | Minimum power consumption |